by Alessia Amelio, Roberto Boccagna, Maurizio Bottini (University of Chieti-Pescara “G. D’Annunzio”) and Massimo Petracca (ASDEA srl)

We present a comprehensive strategy for assessing structural health conditions that we believe could become the standard procedure. The proposed solution covers the entire structural health monitoring (SHM) process, from data recording to damage management. The key innovation of our approach is through the elaboration of a logical workflow reinforced by the use of integrated high-performance devices and hardware/software components designed by ASDEA srl specifically for use in this context.

Artificial Intelligence (AI) has definitively changed perspectives on data analysis and prediction making due to the reliability of AI-based algorithms and the enhanced performance of the currently available processors, which ensure large amounts of data can be analysed in near real-time. These aspects have made AI popular in the fields of civil and structural engineering, where Machine Learning (ML) and Deep Learning (DL) techniques are being used to classify signals acquired by sensor networks permanently installed on structures being monitored. The data recorded undergo a pre-processing step in which noise reduction algorithms are applied before extracting relevant features to be fed into the true AI step. Then, an algorithm establishes if the incoming data are anomalous compared to a baseline of healthy data, indicating whether the structure has undergone a change. This automated approach to assessing the health of (typically) large structures is replacing more traditional (and usually more expensive) in-situ inspections, although periodic surveys are still recommended. Nevertheless, AI has the distinct capability to catch inner changes not otherwise apparent, allowing fast repair operations before damages grow, preventing catastrophes.

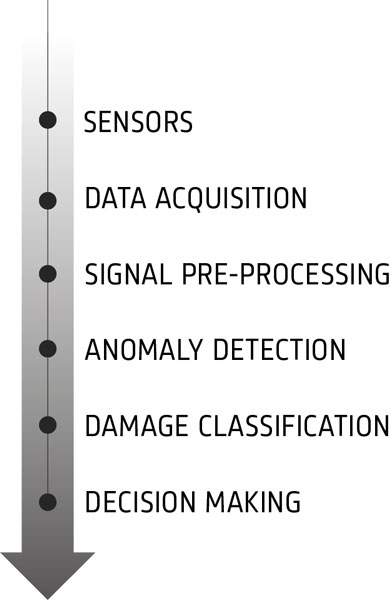

Despite the clear advantages offered by AI in diagnosing structural damage, a precise procedure has not yet been established. The literature [1] shows how various tools have been employed for accomplishing the tasks involved in the SHM sequence, i.e., data acquisition, pre-processing, anomaly detection, damage classification, and decision making. However, these approaches vary wildly in the way they gather and process data, and the lack of a unified and integrated system means that information gained is often incomplete or ineffective. For example, looking at just the first stage of the SHM process, the data acquisition phase, the choice of hardware conditions the functionality of the whole approach. The instrumentation quality alone demonstrates how simple choices condition the rest of the analysis as different sensors measure physical quantities with different sampling rates. Moreover, each sensor has an inherent noise level depending on the hardware components and the way single devices are connected. Even the placement of sensors is critical for obtaining meaningful outputs.

The next salient issue after data pre-processing regards the choice of the algorithm used for damage detection. With reference to the literature [1], many solutions have been adopted for the task with varying levels of success, spanning from classical multivariate statistic techniques to more complex (and generally costly) algorithms involving artificial neural networks. Nowadays, dedicated libraries written in the most popular programming languages contain many AI-based black boxes that can be easily trained for classification issues. However, these obscure many subtleties that must be considered, especially regarding the establishment of relevant features from data, i.e., the engineering parameters most sensitive to small structural variations and a coherent geometry for the chosen classifier.

Furthermore, what makes most solutions implemented so far for SHM unfit is the heterogeneity of data produced in the various stages, as described in Figure 1, and the lack of a common framework for analysis as the software programs used in each stage are typically furnished by different suppliers. Format incompatibilities represent a serious issue, and many problems arise in managing such large, heterogeneous datasets, including a slowdown of the algorithm and, more critically, data loss.

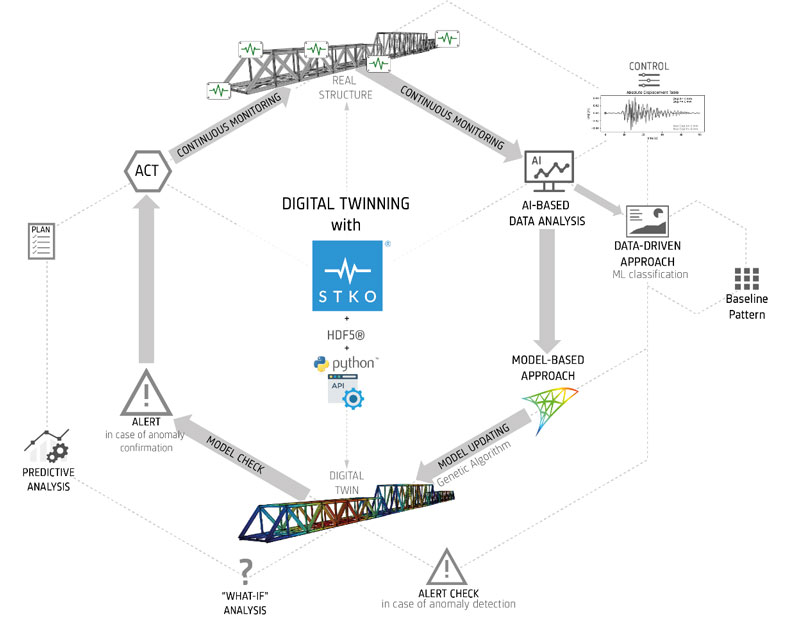

We propose a robust solution that overcomes these problems and manages the whole SHM process in a simple but powerful way through a holistic approach that looks at the system as a whole, instead of the individual parts, aiming at optimal compatibility. The key aspects of our proposed paradigm are as follows:

- A network of optimally placed, high-performance MonStr sensors [L1] for signal acquisition;

- A common environment for analysis provided by the STKO (The Scientific ToolKit for OpenSees) software [L2];

- The adoption of Python 3 as the unique programming language for each part of the algorithm needed to accomplish the flow of operations described in Figure 1;

- The adoption of HDF5 as the only data format.

Figure 1: The sequence defining the SHM process.

STKO was initially created to offer a user-friendly interface for the extremely powerful solvers OpenSees provides for Finite Element Method (FEM) analysis [2]. Beyond that, the software leaves room for customisation, as users can insert Python scripts for special purposes, meaning the entire algorithm for damage detection can be fully integrated within this framework. The environment is already able to construct a digital twin of the structure. Alarms emitted by the data-driven algorithm can be checked immediately by running dynamic simulations, using corresponding recorded data as boundary conditions for the analysis, preventing the emission of false alarms and helping classify damages by location and extension if present. Notice that in this logical framework, no compatibility issues arise; all the I/O operations are managed using the same HDF5 data format, and each component of the software is designed to perfectly match the others to obtain a coherent anomaly detection machine. The entire workflow is described in Figure 2.

Figure 2: The proposed workflow for SHM.

Within this carefully thought-through workflow, one can integrate any classifier desired by writing a specific code or borrowing any ML tool Python makes available, such as Python’s Tensorflow library or Apache Spark, for which GPU programming is easily accessible to speed up computations. These libraries provide many variants of artificial neural networks, which at present are the most promising for this task, beating all other AI techniques.

Our integrated system offers an elegant solution to the most pressing problems in structural health monitoring. We believe it will pave the way toward a standard paradigm for Artificial Intelligence-based SHM [3].

Links:

[L1] https://asdeahw.net/MonStr_O.pdf

[L2] https://asdeasoft.net/?product-stko

References:

[1] D. A. Tibaduiza Burgos, R. C. Gomez Vargas, C. Pedraza, et al.: ”Damage identification in structural health monitoring: A brief review from its implementation to the use of data-driven applications”, Sensors, 20(3), 733, 2020.

[2] M. Petracca, F. Candeloro, G. Camata: “STKO: a revolutionary visualization toolkit for OpenSees” in OPENSEES DAYS Europe, First European Conference on OpenSees, Porto, 2017.

[3] L. Aceto, G. Quaranta, G. Camata, et al.: “Optimum design of a hybrid isolation device for server racks using constrained differential evolution algorithm”, in COMPDYN, 8th Int. Conf. on Computational Methods in Structural Dynamics and Earthquake Engineering, Athens, 2021.

Please contact:

Alessia Amelio, INGEO, University of Chieti-Pescara, Italy,

Maurizio Bottini, INGEO, University of Chieti-Pescara, Italy,