by Michael Sonntag, René Mayrhofer (Johannes Kepler University Linz) and Stephan Schraml (AIT Austrian Institute of Technology GmbH)

The inspection of collector corridors or cable ducts requires permanent and large effort. Aiding (and in the future perhaps automating) this is important for many infrastructure operators. The INFRASPEC project [L1], a two-year project that started in December 2022, improves these periodic reviews by employing a mobile robot to automatically acquire the current physical state, check for missing/added objects and verify the absence of dangerous elements (e.g. gases).

All kinds of infrastructure corridors for transporting water, energy, cooling/heating, etc. require mandatory periodic review. Not only is this a potentially dangerous (e.g. poor ventilation, little space) and costly activity, but it is also usually quite boring and therefore prone to overlooking certain defects. Even small differences to the previous state may be important: increased accretions may hint at water seeping in, small variations in physical measurements hint at structural integrity problems, a missing fire extinguisher may have been stolen – implying access by outsiders, and a toolbox might have been left behind on the last repair – or by a terrorist.

The INFRASPEC project aids these reviews by using a mobile robot, which performs high-resolution laser scans of the environment combined with colour photographs. In this way an automatic comparison to the state from a previous review becomes possible regarding the physical characteristics (deformation of the tunnel or any of the ducts/pipes/cables/trays/ therein, discoloration/change in size of markings, etc). If such an inspection is performed for security reasons, sensors for detecting explosives or other harmful substances (in addition to, e.g. simple gas/CO/CO2 sensors, depending on the existing ducts) can be added. This not only shows deliberate attacks, but also allows detection of invisible leaks (e.g. gas, hole located on the backside of a pipe, currently leaking only into the inside of the insulation). In addition, this does not require a human to actually enter the corridor – they can remain at its opening, or in the future perhaps even outside, for safety.

Moreover, for detailed inspections, a robotic arm is added to allow for example the inspection of a specific pipe that might have a leak or hidden areas that had not been covered before. For safety reasons, this arm needs collision avoidance, so it is even inadvertently impossible to damage any elements within the corridor – the arm could easily destroy for example insulation of cables or pipes. This is based on the 3D scan and dedicated sensors on the arm itself, from which a safe trajectory/position and orientation can be calculated. For the inspection itself, the arm at the moment carries only a video camera, so the operator can inspect the suspected damage from close up. Further sensors (e.g. IR-camera) which may help to detect certain flaws more easily are being contemplated.

As such inspections often must be proven to a supervisory authority, evidence of their execution and of the results must be created. Note that the inspecting person/infrastructure operator must be considered potential attackers here also (e.g. only claiming to have performed inspections without actually doing them). To implement the required auditing, a dedicated evidence-collection subsystem is being added (see [1] for details). The communication (similar as for the resulting data) needs to be protected against various threats, so data transfer between base station and robot needs to be secured and transparently integrated into the evidence collection to be able to log clear-text data.

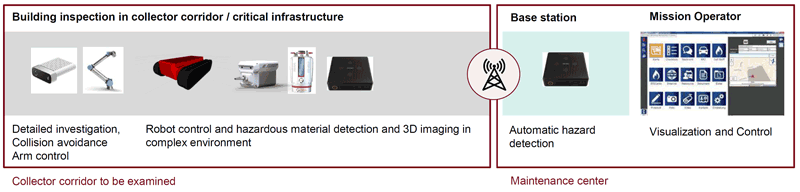

The system (see Figure 1) is separated into two parts: the mobile platform, i.e. the robot, with the sensors and the arm; and the base station. As some tasks are time-sensitive, for example collision avoidance, some data is evaluated on the robot itself by an additional computer. As this is a research project, the communication with the base station is implemented by WLAN only (which perhaps means a limited operational range in ducts). The base station performs the 3D model construction as well as comparison to previous scans and the detection of potential problems, the integration of the other sensor data into the UI for the operator and the evidence collection.

Figure 1: System overview.

For the end of the project, a demonstration at a physical location is planned, where all the aims (laser scanning and detection of the various potential problems, detail inspection with mobile arm and collision avoidance, evidence collection) will be tested.

Scientific partners of the project are AIT Austrian Institute of Technology (3D scans, collision avoidance), Rosenbauer International AG (mobile robot and arm), Johannes Kepler University Linz (IT security, evidence collection), CBRN Protection (sensors for dangerous materials), and Disaster Competence Network Austria (user acceptance, risk analysis, and organisation of tabletop exercise). End users/providers of requirements and test locations are Wiener Netze (cable ducts – energy transmission), Vienna Airport (cable ducts – heating/cooling), and the Austrian Ministries of Interior and Defence (detection of dangerous objects).

This publication and the system described in it is developed within the scope of the project INFRASPEC (FFG project number FO999895182), which is funded by the Austrian security research program KIRAS of the Federal Ministry of Finance (BMF).

Link:

[L1] https://projekte.ffg.at/projekt/4491903

Reference:

[1] M. Sonntag, S. Schraml, “An evidence collection system for robot-supported inspection of critical infrastructure”, in IDIMT 2023, p.51.

Please contact:

Michael Sonntag

Inst. of Networks and Security, Johannes Kepler University Linz, Austria