by Violeta Damjanovic-Behrendt (Salzburg Research)

We have designed a digital twin prototype for detecting security, privacy and safety critical issues for the smart automotive sector, based on work done in the ongoing IoT4CPS project (Trustworthy IoT for cyber-physical Systems.

The ability of smart cyber-physical systems (CPSs) to interconnect and merge into the ubiquitous Web of Things (WoT) infrastructure, facilitates the reuse of web technologies for future application development and reduces implementation time and effort. In practice, however, digital twin platforms are often built as closed, commercial systems, again limiting the pervasiveness of the technology. Thus, in IoT4CPS we design an open source digital twin prototype that employs machine learning (ML) for behavioural analysis and forecasting of security, privacy and safety measures. The proposed prototype creates an open source environment that comprises the following three technology blocks: (i) data collection and management, (ii) computational model management and (iii) (micro-)service management.

Data Collection and Management

One of the desired features for the digital twin is the ability to accurately simulate, analyse and predict real-world events and situations. In order to do so, digital twins require a collection of data describing the physical world, context, events and situations to be “mirrored” in the virtual space. The collected data include expert knowledge, historical data, inferred data, as well as data integrated from other enterprise systems and third-party systems.

Computational and Representational Model Management

Digital twins require a collection of models, e.g. data computational models (dynamic, behaviour models including statistical packages for ML, analytics, optimisation) and representational models (static, structural models including semantic data models, NoSQL, relational data models, rule engines). Data computational models perform analytics and processing along the entire product lifecycle phases, supporting system models, functional models, manufacturing computation models [1]. By employing ML algorithms (e.g. deep learning for neural networks to learn anomalies of the system), inferred data learned during the run time can be incorporated into the digital twin knowledge base, enabling continuous learning and improvement of features of the digital twin.

Service Management

To effectively monitor and simulate the physical world and perform computations leading towards intelligent decision-making for data and process lifecycle, digital twins require a collection of services, e.g. services for real-time state monitoring of the physical product and processes; services for real-time data management and asset management; services for real-time product failure analysis and prediction (anomaly detection); services for application security (authentication, authorisation, etc.), and more.

A Digital Twin Microservices Architecture

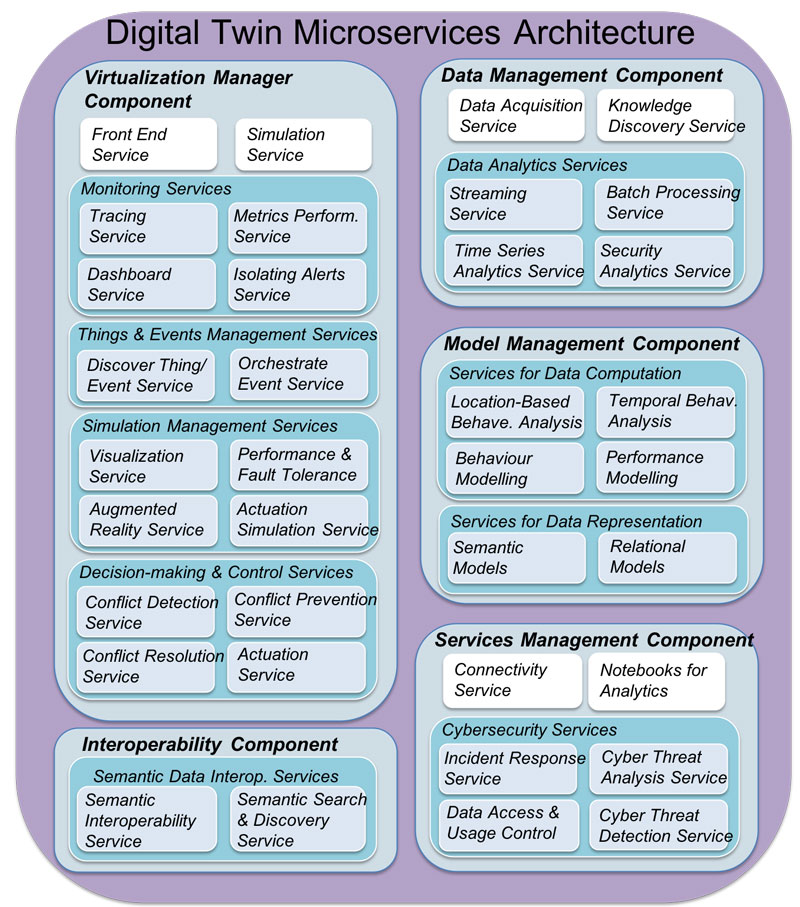

Our architecture of the digital twin follows the microservices approach, and consists of the Data Management, Model Management, Service Management, Virtualisation and Interoperability components, as shown in Figure 1.

Figure 1. Microservices Architecture of the IoT4CPS Digital Twin Prototype.

The Data Management Component includes Data Acquisition Service, Knowledge Discovery Service and Data Analytics Services for streaming, batch- and time series-oriented processing, and security-oriented analyses. The Models Management Component includes (i) Services for Data Computation supporting either temporal or location-based behaviour analysis or performance modelling, and (ii) Services for Data Representation that could be semantic or relational models. The Services Management Component offers services through notebooks for customised analytics, and performs various cybersecurity tasks, e.g. data access and usage controls, threat detection and analysis service, incident sharing and incident response service. The Virtualisation Manager Component operates through front-end services, monitoring services, things & events management services, simulation and simulation management services, and decision-making and control services. Monitoring Services offer end-to-end transaction tracing (Tracing Service), measuring performances and operations of the system (Metrics Performances Service), the ability to isolate problems, alerts, and anomalies (Isolating Alerts Service) and dashboard visualisation services for monitoring interactions and cross-service visibility (Dashboards Service). These services help developers to understand the overall user experience while breaking information down into smaller applications. For example, Simulation Management Services perform visualisation (Visualisation Service) which could use a form of Augmented Reality (Augmented Reality Service) for simulating a specific actuation (Actuation Simulation Service) and measuring system performances and fault tolerance (Performance & Fault Tolerance Service). Finally, the Interoperability Component is designed to offer interoperability mechanisms at the data level (Semantic Interoperability Service and Semantic Search and Discovery Service).

Conclusion

The Smart Automotive sector is fragmented by different strategic alliances of manufacturers. This makes it difficult for research to offer novel, alternative approaches to autonomous decision making, context- and situation-aware controls and self-adaptation, all of which are required to realise smart CPSs. Hence, in IoT4CPS, we design a flexible digital twin open source solution that can offer alternatives to proprietary technology stacks developed in corporate automotive research.

This research has been funded by the Austrian Research Promotion Agency (FFG) and the Austrian Federal Ministry for Transport, Innovation and Technology (BMVIT) within the “ICT of the Future” project IoT4CPS [L1].

Link:

[L1] https://iot4cps.at/

Reference:

[1] J. Rios, et al.: “Product Avatar as Digital Counterpart of a Physical Individual Product: Literature Review and Implications in an Aircraft System.” In Proc. of ISPE CE2015, Vol. 2 of Advances in Transdisciplinary Engineering, 657–666, 2015.

doi: 10.3233/978-1-61499-544-9-657

Please contact:

Violeta Damjanovic-Behrendt

Salzburg Research, , Austria

+43 662 2288 427