by Felix Strohmeier, Christoph Schranz and Georg Güntner (Salzburg Research)

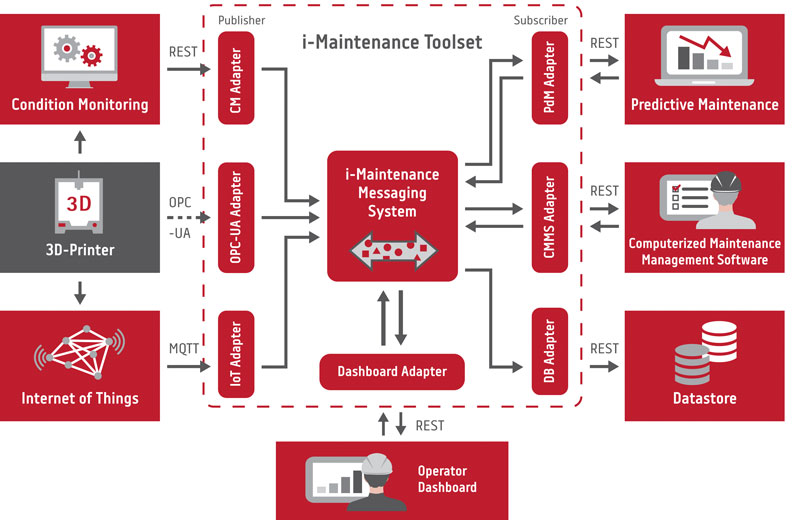

The i-Maintenance toolset is a messaging system that constitutes the technical foundation for digital twins of industrial assets by collecting, monitoring and analysing life cycle data. The messaging solution can be used in an innovative way to set up a prototypical digital twin of a production asset by integrating maintenance management, condition monitoring, IoT and predictive analytics solutions.

In a digitised production environment, maintenance operations and long-term asset strategies can be considerably improved by having precise knowledge about the current state of machines and other equipment in combination with historical data of the same. Increasing the overall equipment effectiveness (OEE) requires a reliable and scalable flow of lifecycle and status information generated throughout the production process.

The work described in this article is carried out in the innovation network “i-Maintenance”: In this project, we develop a toolbox consisting of methods and tools supporting the digital transformation of industrial maintenance activities. One of the proposed technical tools, the i-Maintenance toolset, provides a messaging solution and a set of adapters for integrating sensor/actuator systems and other software components in a maintenance scenario. The goal is to create a comprehensive digital twin of an industrial asset to gain insights into the status of all components related to the production and maintenance process and to enable a seamless communication between the proprietary tools provided by our project partners.

A proof-of-concept demonstrator is implemented based on the architecture shown in Figure 1. In the laboratory setting at Salzburg Research, a 3D-printer takes the role of a production asset. Maintenance tasks are managed by means of a Computerised Maintenance Management Software (CMMS). The 3D-printer has been equipped with external sensors, a video camera and a condition monitoring system. Data collected from the printer and its environment is used to predict maintenance tasks: Cleaning the hot end (“the nozzle”) is required at irregular intervals depending on usage, parameter settings and environmental conditions. The predictive maintenance software provides recommendations for maintaining the nozzle. Finally, a dashboard supports operator activities like filament changes or nozzle cleanings.

Figure 1: Architectural overview of the i-Maintenance toolset.

The i-Maintenance toolset consists of a messaging bus and a set of adapters, for each of the external software components. The messaging bus serves as a communication layer and is responsible for receiving and distributing the information between those applications. The main role of the adapters is the translation of application-specific data formats into a common message format that is used by all participants of the messaging system. For the semantic description of data, the open OGC SensorThings [1] standard has been selected. This data representation requires just a minimal amount of mandatory information per message and is also linked to the complete datastream definition stored on a standardised SensorThings server. Each message contains a result value, two timestamps (phenomenonTime and resultTime) and the datastream identifier.

To meet the high demands of “smart factories” in terms of performance and stability, messages between the adapters are transported using the scalable, fault-tolerant data streaming platform Apache Kafka [2]. In contrast to other messaging protocols, such as MQTT or AMQP, Kafka is designed differently: To offload state processing from the brokers, more intelligence is put to the publishers and subscribers. This results in overall performance advantages, allows horizontal scaling and improves reliability. New applications and IoT protocols like OPC-UA, REST or MQTT can be connected with little effort via the adapters.

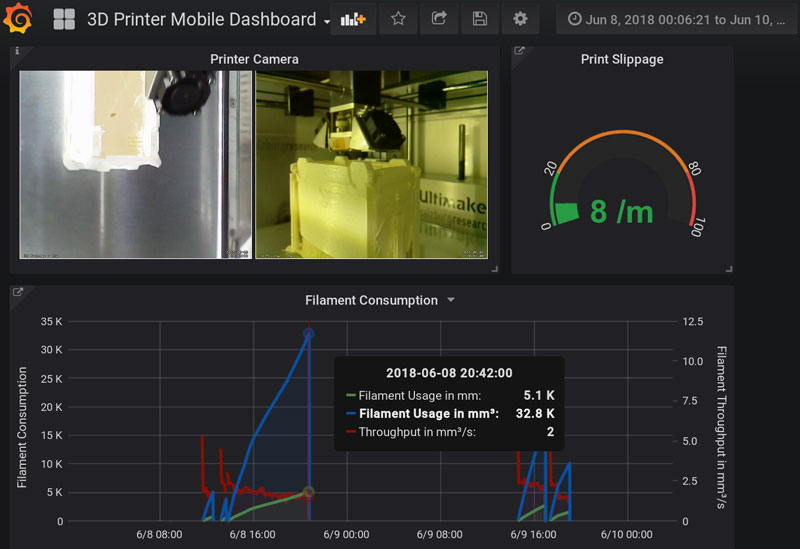

In order to set up a comprehensive digital twin for smart maintenance, all messages of all topics are streamed into a separate “datastore”. Due to the common SensorThings format, the information can be effectively queried and filtered. As technology for implementing the datastore, we use Elastic Search from the “Elastic Stack” (https://elastic.co), which is also horizontal scalable and distributed: storage and processing power can be added by putting more nodes to the cluster. For a user-friendly visualisation of real-time sensor data and video streams, “Grafana” (https://grafana.com) is integrated, where the cause of production failures during the 3D-printing process can be investigated live or retrospectively (Figure 2). For advanced analytics of data generated throughout the production process, the “Jupyter” framework (https://jupyter.org) is connected. It enables collaborative work on the same project via browsers with a variety of interpreters like Python, R and Scala. This makes it possible to invite remote experts for data analytics and assessment, without the need to send huge amounts of sensor data and log-files. User-specific data analytics represents a frequently neglected aspect of a digital twin framework.

Figure 2: User-friendly analytics for real-time or retrospective investigation of failures.

Figure 3: Laboratory setting at Salzburg Research.

At the time of publication of this article, the i-Maintenance toolset is validated against a set of functional and non-functional criteria for digital twins in a maintenance scenario. In future, additional lifecycle and analytics features will be developed together with further adapters to cover more industrial protocols.

i-Maintenance is funded by the Austrian Federal Ministry for Digital and Economic Affairs (BMDW) and the Austrian Research Promotion Agency (FFG) in the COIN programme. Conducted by Salzburg Research, the development of the i-Maintenance toolset is supported by H&H Systems (ispro-NG), Messfeld GmbH (condition monitoring) and Intelligent Predictive Networks GmbH (inCARE).

Links:

https://srfg.at/i-maintenance

https://github.com/i-maintenance

http://www.maintenance-competence-center.at/

References:

[1] Open Geospatial Consortium: "OGC SensorThings API Part 1: Sensing",

http://docs.opengeospatial.org/is/15-078r6/15-078r6.html

[2] J. Kreps, N. Narkhede, J. Rao: “Kafka: A Distributed Messaging System for Log Processing”, NetDB workshop 2011, https://www.microsoft.com/en-us/research/wp-content/uploads/2017/09/Kafka.pdf, https://kafka.apache.org

Please contact:

Felix Strohmeier

Salzburg Research, Austria

+43 662 2288-443