by Stefan Boschert and Roland Rosen (Siemens AG)

Railroad switches, also called turnouts or points, are a key element of the rail network infrastructure. They are distributed all over the network and their maintenance is crucial to guarantee safety and undisturbed operation. Within a railway network, the turnouts are responsible for a high amount of the operational costs as monitoring and maintenance is mainly manual. Using a combination of measurement data and physics-based simulations – a typical Digital Twin application – has a high potential to identify failures before they become critical. Defining a general methodology to derive such solutions which make use of all the relevant information created along the lifecycle is the subject of our current research.

Recently, the Digital Twin has become very popular, appearing as one of Gartner top10 technical trends for 2017 and 2018 [1]. Here it is defined (in an IoT context) as a digital representation of a real-world entity. The Digital Twin collects all information on the state and usage of physical entities and links it to information on the state of counterparts and provides support reaction to changes, thus adding value to the usage of the entity.

The exclusive focus on the data-mining aspect of the Digital Twin neglects an essential aspect of the original idea of having a digital companion throughout the lifecycle of all entities. The general concept behind the Digital Twin dates back to Michael Grieves’ 2002 presentation in which he presented a “Conceptual Ideal for PLM”. This Ideal contained all important elements of the Digital Twin: real space, virtual space, information flow from virtual space to real space and virtual sub-spaces [2]. The term “twins” seemed appropriate given the duality of real space and virtual space and the ability to use whichever is most suitable for a given problem. NASA had already used such an analogy during the early Apollo program to reference duplicate space vessels that remained on earth and were used to mirror the actual flight conditions.

The terms Digital Twin prototypes (DTP) and Digital Twin instances (DTI) were introduced to distinguish the different character and purpose of the Digital Twin [2]. In the early lifecycle phases, the DT consists mainly of artifacts used to optimise the product functionality. The digital models are used to check design alternatives and to test product functionalities against its requirements using virtual prototypes (the Digital Twin prototype). This approach greatly contributes to reduce time and costs during product development. On the other hand, the DTI emphasises the aspect that with each individual physical entity, (digital) information is also collected through the whole lifecycle. This need not be limited to sensor and operation data, but may also include information from its production (e.g. supplier or production line). With the rise of sensors everywhere, a vast amount of data is available to be linked to the DTI. Also, as the DTP focuses on the general behaviour of the entity, it can be seen as a common part of each DTI and can be exploited to create solutions.

The models included in the DTP are usually created for very specific design questions. Therefore, many different models tend to be available for the same component, each representing a different design question on an appropriate model granularity. Modern PLM systems help to archive and to keep track of these models. However, a vast amount of models and even more resulting data are created during the engineering phase, the sum of which cannot be maintained; a first decision on what models and data are preserved has to be taken. This makes it difficult to deduce new models for novel application fields occurring in the operation phase, as information on the limitations and assumptions and underlying ideas on the existing models are probably no longer available. On the other side, in many cases it is already foreseeable which questions will be asked during the operation phase to the product, or in other words, which functionalities the Digital Twin of the product has to provide for the operation phase. Therefore, it is sensible to design these Digital Twin features in parallel with the product as shown in the example of the Digital Twin of a point machine used for failure identification [3].

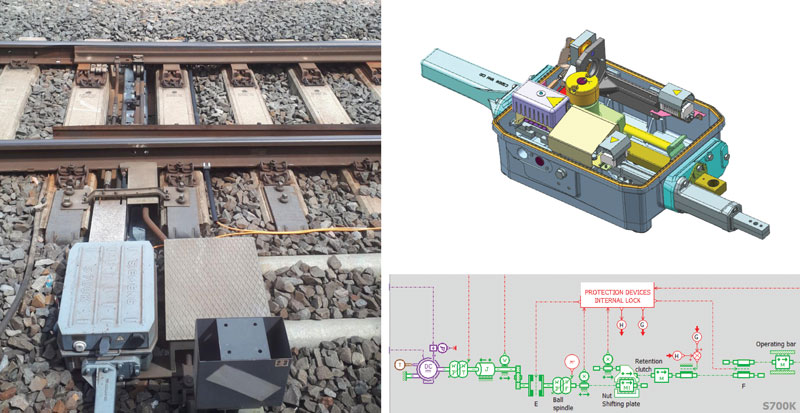

Figure 1: Point machine (left) and simulation models of different granularity (right).

The interactions between railway switch and its drive (point machine) are complex. Many different physics-based models are used to verify that the design guarantees a safe operation during the whole lifetime. During the operation of the point machine in the field, the actual conditions and possible looming failures are of interest for the operator. The detailed models used to engineer the system already contain most of the ingredients to create the tools to handle these questions. Therefore, these models are enhanced to be able to simulate possible failures during the time when the models are created initially. To this end, they have to be simplified (e.g. by deducing 1D models from complex 3D simulations) and to be configurable for individual situations. This requires only a little extra effort compared to the complete re-modelling necessary if the models were to be created during operation phase. It is essential that these models are treated as an integral part of the product so that they too are maintained to remain operable (e.g. get necessary software updates). During the instantiation (i.e. the actual dispatch of the point machine on the track) some configuration parameters – specific to the current configuration e.g. turnout-radius – have to be set in the model. The DTP is now individualised to become the specific DTI for this turnout. By using this simulation model and comparing its results to current sensor data from the track, looming failures can not only be detected but also their root-cause can be identified and so tailor-made maintenance measures can be deduced. The engineering models that required considerable resources for their initial creation thus have a second use. And the availability of the railroad tracks and thus the riding comfort is significantly increased.

References:

[1] “Gartner top 10 Strategic Technology Trends for 2017”, received from https://kwz.me/htG

[2] M. Grieves, J. Vickers: “Digital Twin: Mitigating Unpredictable, Undesirable Emergent Behavior in Complex Systems”, in F.J. Kahlen et.al.: “Transdisciplinary Perspectives on Complex Systems”, Springer 2017

[3] S. Boschert, R. Rosen, C. Heinrich: “Next Generation Digital Twin“, in: I. Horvath et al (Eds.) Proc. TMCE 2018, S.209-218.

Please contact:

Stefan Boschert, Roland Rosen,

Siemens AG, Germany