by Alexandros Fragkiadakis (FORTH), Theoharis Moysiadis (Future Intelligence Ltd) and Nikolaos Zotos (Future Intelligence Ltd)

Traceability allows the identification and tracking of products as they travel through the supply chain, from the manufacturer to the consumer. Smart Product [L1] is a research project aiming to design and develop a secure IoT-based architecture for supply chain traceability, product origin verification and authenticity certification.

The Internet of Things (IoT) has revolutionised the technological means that have made feasible the interconnection and interaction between the physical and digital worlds. Billions of devices, worldwide, sense the physical world (ambient temperature and light, humidity, weather conditions, etc.), leading to the proliferation of numerous applications and initiatives including smart cities, e-health, precision agriculture, etc. Another area that IoT technologies can be successfully exploited is supply chain (SC) traceability, where products are recorded as they travel from the manufacturer to the consumer. An IoT system can read data from a plethora of devices such as smart tags (RFIDs, NFC, Barcodes, Bluetooth Low Energy), along with sensory data like ambient temperature and humidity, vehicle speed, geolocation, and if intelligently combined together, can effectively track the SC.

SC tracking offers numerous advantages to all parties involved (producers, retailers, consumers): food safety (quality deviation management, recalls in food crisis), perishable product protection, origin verification and brand certification, customer engagement and loyalty programs, monitoring, control, planning and optimisation of business processes remotely [1]. Furthermore, the utilisation of IoT technologies can offer low cost services, as the cost of sensors and other related equipment (tags, etc.) significantly decreases over time, owing mainly to the technological advances of the hardware manufacturing industry. At the same time, IoT technologies (communication protocols, interoperability standards, IoT/cloud architectures, security & privacy algorithms) have substantially matured. For these reasons, IoT-based SC tracking appears as an appealing and feasible solution.

The aim of the Smart Product project [L1] is the design, implementation and evaluation of an IoT-based platform for SC tracking, product authenticity certification and verification of origin, and consumer engagement. The platform will utilise IoT technologies at the device level (tags, sensors), as well as software and communication protocols, with emphasis on interoperability, energy-efficiency, security and privacy. This project aims to cover various weaknesses of existing SC tracking systems, such as: lack of monitoring beyond retail, lack of transparency, lack of usability, flexibility and immediacy, fragmentation of technologies and lack of interoperability.

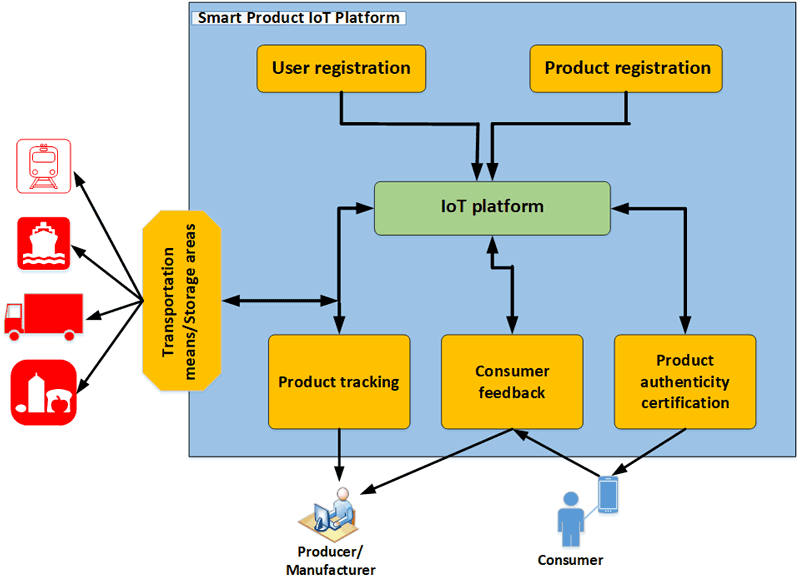

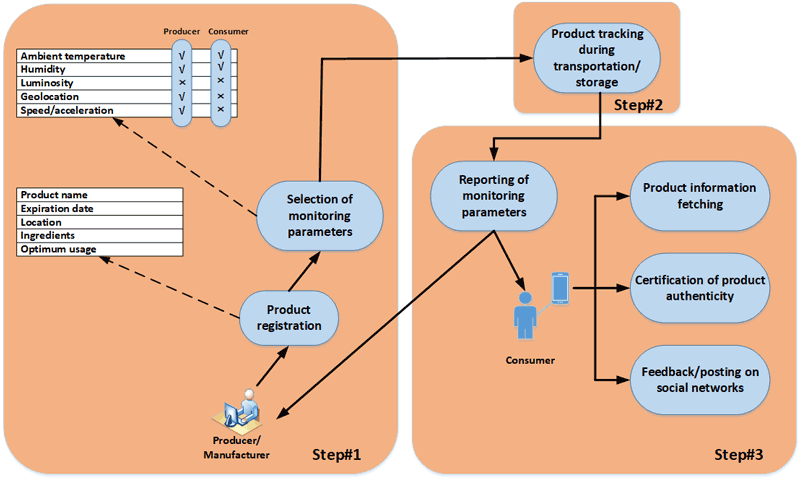

Figure 1: Smart Product IoT platform conceptual view.

At operational level, the Smart Product project will provide technological solutions by making the following feasible (Figure 1):

- SC tracking by recording product-related information such as storage conditions, geographical locations of production, storage and sales. This will make it possible for the producers to monitor the products, partially addressing the availability of products in areas where for various reasons it is not allowed (e.g. exporting smuggled products to other countries), but will also enable consumers to be informed about the origin of the products and their storage conditions during transportation. Prerequisites for successful monitoring and recording are: the existence of a smart label on the product or a package containing a number of identical products, the existence of equipment for reading the smart labels, the existence of equipment for measurement of storage conditions, such as ambient temperature and humidity sensors, and an appropriate database for data storing.

- Certification of products’ authenticity and origin, limiting the distribution of counterfeit products and thereby increasing consumer confidence in genuine products. The prerequisites for making this possible are: the introduction of relevant product information into an appropriate database by certified users (producers, etc.), the existence of a smart label on the product that indicates with appropriate coding the identity of the product, and appropriate equipment for reading the smart label, such as a smart phone with the ability to read such labels.

- Stimulate consumer engagement with products through a smart phone application. Consumers, in addition to certifying the authenticity of the products, will be able to obtain further information on the product in question, such as its ingredients, how to use it, etc. By creating appropriate user interfaces on social networks, consumers will be able to further engage with producers/ marketers through appropriate marketing methods.

The platform will be demonstrated and evaluated through a concrete use-case (Figure 2) that employs producers/manufacturers and consumers, consisting of three steps:

Step#1: A producer/manufacturer registers their product on the project platform, receiving a unique code that identifies it (e.g. Electronic Product Code) that is further stored in the platform’s database. It will also be possible to state the monitoring parameters during product traceability (storage temperature, humidity, etc.). Product related information such as optimum usage patterns, ingredients, geographical location of production, expiry date and activation of feedback to producers/manufacturers will also be posted. In addition, it will be determined which of the above information will also be available to the consumers.

Step#2: The products are monitored during their shipment from the place of manufacturing to that of disposal. Both in the storage and in the transport vehicles, there will be sensors that will record the monitoring parameters selected in Step#1. At the same time, the unique code of the transported products will be recorded and linked to the monitoring parameters while stored in the database.

Step#3: The product is already on the shelf and steps # 1 and # 2 have been followed. The product bears a smart label that is read by a smart phone application that further communicates with the platform and collects all available data about the product and imprints it on the mobile screen for consumer information. Through the same application, consumers can send feedback to the producer/manufacturer, and can post on social networks their experience with the specific product.

Figure 2: Supply chain tracking use-case.

The consortium consists of two partners, FORTH and the Future Intelligence Ltd that receive funding from the Operational Program of the Region of Epirus, Greece.

Link:

[L1]: https://www.smartproduct.gr

Reference:

[1]: C. Verdouw et al.: “Virtualization of food supply chains with the internet of things”, Journal of Food Engineering, Elsevier, 2015.

Please contact:

Alexandros Fragkiadakis

ICS-FORTH, Greece,

Theoharis Moysiadis

Future Intelligence Ltd, Greece

Nikolaos Zotos

Future Intelligence Ltd, Greece,