by Christos Koulamas, Petros Pistofidis and Christos Emmanouilidis

In the modern era of global competition, reduced financial operation margins, and rapid market changes, enterprises cannot afford to underutilize their resources. The efficiency of a production line is largely influenced and ultimately defined by the reliability of its technical equipment. Optimal and cost-effective management of engineering assets is essential. This cannot be achieved with the traditional “fail-and-fix” policies (corrective maintenance). Rather, a more proactive preventive maintenance is necessary.

Condition-based maintenance (CBM) is a maintenance management strategy that plans maintenance actions on the basis of the actual machinery or asset condition, as opposed to predetermined (e.g. scheduled) maintenance. A CBM strategy presupposes the implementation of condition monitoring, that is the process of monitoring machinery condition parameters in order to infer the machinery condition and offer maintenance actions recommendations accordingly. Maintenance-related data and services must be ubiquitously and transparently available at anytime, anywhere, to any authorized person. This is key towards realizing e-maintenance.

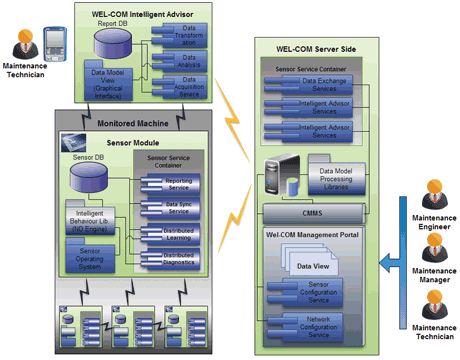

The WelCOM platform [1], depicted in Figure 1, is moving in this direction. It offers multi-layered intelligence for the optimal operation and maintenance (O&M) of the equipment during its productive period (middle-of-life). At the device level, an innovative and versatile optical sensor is designed and ported in both wireless and wired form which can be used for diverse monitoring applications.

Figure 1: The WelCOM platform

The optical sensors are integrated in networked embedded systems forming a wireless sensor network that can sustain operation in industrial settings. The wireless sensor network nodes implement a distributed sensor-embedded intelligence based on condition state models and a novelty detection engine. The overall system integrates real-time condition monitoring and novelty detection with accurate fault diagnosis; support of prognosis and prediction of failures; and effective notification for immediate attention and maintenance.

The maintenance data can be provided by heterogeneous sources; hence data integration is a major obstacle for wide adoption. To this end, maintenance information modelling will be utilized and based on open specifications. Domain ontology has been developed to express the semantics for the maintenance problem space based on the MIMOSA OSA-CBM specifications [2]. Also, data interoperability and exchange formats and interfaces have been defined so as to allow seamless information flow between the wireless sensor network layer and the knowledge management layer.

The WelCOM configuration and management portal will offer all authorized personnel access to real-time, on-the-spot sensor feeds of modelled machine state data, while traditional CBM approaches allow only delayed, off-line processed information. The portal will couple services and sensor software components as to enable “zooming” from the administration level down to managing and calibrating any single sensor device of the monitoring network.

The knowledge produced within the platform is not only available in the control room. A significant component is the portable intelligent maintenance advisor. This module is available as a software for portable devices (laptops, tablets, smartphones, etc.) that scans through the knowledge portal and retrieves proper “knowledge objects” to aid the maintenance practice of a technician in the field.

Finally, a training module will be integrated into the WelCOM platform aiming to achieve a defined level of competencies for maintenance technicians by harnessing the derived knowledge. The e-training is a practical and cost-effective alternative to expensive on-the-job training.

This research is conducted by a Greek public-private partnership between the Research and Innovation Center Athena (including its Industrial Systems Institute) and the NHRF public research institutions and Kleemann Hellas Lifts, Prisma Electronics, GDT, and Atlantis Engineering as industrial partners. The project is supported by the GSRT (grant no. 09SYN-71-856).

Link: http://welcom-project.ceti.gr/

References:

[1] P. Pistofidis et al, (2012), A Layered E-Maintenance Architecture Powered by Smart Wireless Monitoring Components, presented at the 2012 IEEE Conference on Industrial Technologies, ICIT 2012, 19-21 March 2011.

[2] MIMOSA - An Operations and Maintenance Information Open System Alliance web site http://www.mimosa.org/

Please contact:

Christos Emmanouilidis, Athena RIC, Greece

E-mail: