by Zsolt Kemény and Elisabeth Ilie-Zudor

In the past, fast and affordable shipping of small consignments was perceived by the logistics industry as a conflict of requirements. Recent decades, however, have shown that bundling and rebundling of shipments enables certain types of logistics networks to comply with both criteria at the same time. Usually, these networks follow a multi-level hub-and-spoke layout with a high-throughput central player and independent and agile local collection and delivery partners. Meanwhile, however, performance limits have surfaced, most of them owing to organisational heterogeneity and resulting degradation of process transparency. Since late 2010, the FP7 EU project ADVANCE has been tackling these challenges and providing a re-usable framework for modelling and solving problems inherent to hub-and-spoke networks.

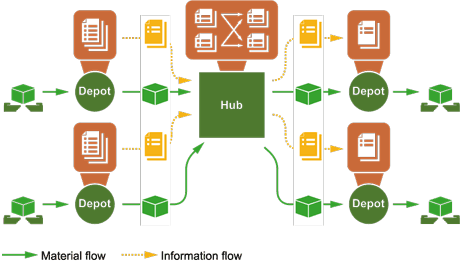

Past decades have demonstrated the feasibility of networks with an efficient core of one or more hubs, and a periphery of flexible local pick-up and delivery services acting as spokes. Inbound shipments are bundled in the originating depot by source area, and are rebundled at hubs by delivering spoke (depot). Inbound and outbound services are typically operated by the same local fleets. However, hub-and-spoke networks operated with sub-contracted depots still have room for improvement by addressing the following issues:

- The organizational heterogeneity of depots (different policies, handling of shipment information, etc.) impairs interoperability. This also covers reliability, the timing of sharing information, etc.

- Multiple-participant networks can suffer from information not being available in a given place at the right time (ie data flow may lag behind the material flow), resulting in sub-optimal decisions and inefficient or unbalanced use of transportation assets. This is critical if the same vehicles perform both depot-to-hub and hub-to-depot traffic and leave/arrive by the same schedule.

- In a large network, the amount of data presents its own challenges in addition to the challenges associated with surveying longer time ranges to detect trends or patterns. Massive but low-level information must be prepared for decisions, forecasts, etc. The implicit knowledge of demand dynamics and dependencies is currently largely unexploited.

- Confidentiality issues may also arise if members collaborating within the network compete on other services. While participants strive to disclose a safe minimum of information, it may be possible to employ privacy-preserving techniques.

- Making participation attractive may conflict with overall network efficiency. This hindrance is well-known in other related domains, such as supply chain management (SCM), and has been addressed by various risk-sharing and profit-sharing contracting policies.

Figure 1: In complex logistics networks, data accompanying the shipments are just as important as the material stream itself—in certain cases, shipment data have to be filtered, reformulated, or need to precede the material flow for adequate allocation of resources. This is not a trivial challenge and has to comply with constraints as privacy of network participants.

The European R&D project ADVANCE addresses several of the aforementioned challenges with a solution framework providing data transformation, filtering, model building and prediction tools for operational-level decision support. Working closely with the UK-based company, Palletways, gives the project consortium an excellent background for in-depth field studies, and allows objective testing of pilot applications. The project will deliver:

- Runtime environment and flow editor. Dispatching and processing massive low-level information requires an efficient runtime environment. To this end, the ADVANCE project employs the reactive approach whose asynchronous, event-oriented characteristics guarantee the lean usage of computational resources. The framework uses data models specifically targeting the logistics sector. Nevertheless, these are kept flexible enough for deployment in other networks. IT staff adopting the framework to specific use cases will have a flow editor at hand. This is, in essence, a graphical programming interface for laying out connections between functional blocks before run-time use, with advanced productivity and verification features (e.g. type probing of data channels and type inference).

- Exploiting low-level information. Today’s logistics networks are characterized by massive but distributed low-level data where relevant information may be implicit or remain localized. This apparent challenge bears much potential which the ADVANCE project aims to harness. Machine learning techniques are employed to build process models and extract relevant information, making it available for operational decisions or on-demand forecasts.

- Decision support on the operational level. ADVANCE envisages decision support functionalities in various forms, appropriate for different situations. Where needed a model-based prediction produces forecasts whilst in other cases, warnings are issued to call the operator’s attention to the need for intervention. The evolvability of decision support is highly dependent on the way in which the results fit into the operator’s mental context; in other words, it is best if the way the suggestion is presented “makes sense”. In the ADVANCE project, cognitive models of human reactions are employed to adapt to the nature of human comprehension, attention and misconceptions.

Started in 2010, the three-year R&D project ADVANCE is financed within the EU 7th Framework Programme, and has already successfully completed its first year. Led by SZTAKI of Hungary, the consortium also includes academic members from the UK (Aston University) and the Netherlands (RUG), an Italian IT development company (TTS), and UK-based logistics company Palletways, the latter hosting pilot applications and field tests. Generic parts of the project’s output will be freely available to the public.

Link:

http://www.advance-logistics.eu/

Please contact:

Elisabeth Ilie-Zudor

SZTAKI, Hungary

Tel: +36 1 279 6195

E-mail: