by Joachim Arts, TU Eindhoven

Capital goods, such as trains and railway infrastructure that facilitate our public transport, are an important part of our daily lives. Maintenance operations are necessary to ensure safety and prevent disruptive failures. To make these operations run smoothly, it is crucial to have the right amount of spare parts available. Eindhoven University of Technology and NedTrain collaborate to optimize the spare parts supply chain using stochastic modelling and optimization.

Interchangeable parts have revolutionized modern manufacturing, but the idea was originally born as a maintenance logistics innovation by a French general by the name of Jean Baptiste de Gribeauval. When artillery or other equipment broke down during battle, performing the repair would usually take longer than the battle itself, rendering equipment useless for the remainder of a battle. Gribeauval made a plan to construct equipment from interchangeable parts such that repair could be performed quickly by replacing the broken part. The broken part is then repaired offline to be used in a future exchange of parts. This method of repair-by-replacement is now common in the maintenance logistics operations of many asset owners in the rail, aerospace, medical devices, defence, and other industries.

To successfully run a repair-by-replacement system, logistics managers and engineers need to make several decisions, the most important of which are:

- How many spare parts of each type do you need?

- How do we decide which broken parts need to be repaired with priority?

Smart methods to make these decisions have large financial and societal consequences. Expenditure on spare parts in the USA in 2003 and 2006 constituted 8% of GDP (see e.g. [1]). Temporary unavailability of a spare part can lead to delayed or cancelled trains and flights, standstill of large manufacturing plants, and rescheduling of medical procedures that need specialized equipment, among many other adverse societal consequences. Therefore Eindhoven University of Technology and NedTrain set up a collaboration to answer these questions within a larger research program of NedTrain in rolling stock lifecycle logistics.

Fluctuating demand and expediting repair

NedTrain, a subsidiary of the Dutch railways, is responsible for the maintenance of most of the rolling stock in the Netherlands. Their core business is to run a repair-by-replacement system so that rolling stock is always available to carry passengers according to the time table. The spare part supply chain of NedTrain and many other companies has two important characteristics:

- Demand for spare parts is a non-stationary stochastic process that results from degradation processes and maintenance planning. This means that demand intensities fluctuate over time.

- The repair lead time of a broken part can be shortened but only for a limited number of all the repairs handled by a repair shop. Typically this is done when the stock of ready-for-use parts is critically low.

Natural questions that arise in this setting are:

1) When should the repair of a spare part be expedited?

2) How do optimal expediting policies and stocking decisions depend on the way demand fluctuates over time?

3) Can we reduce the spare parts inventory investment by using the answers to the previous questions in a smart way?

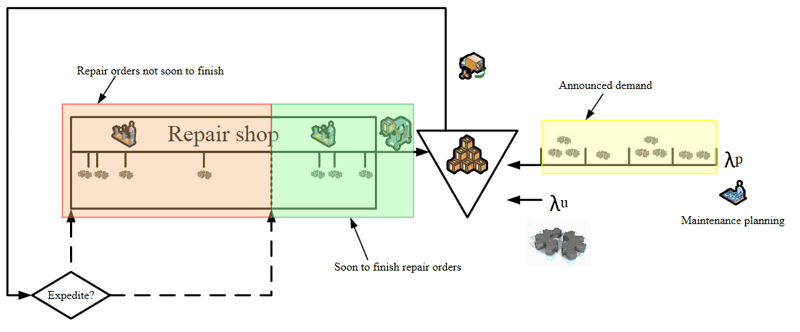

Structural results for optimal expediting policy

We constructed the model shown in Figure 1 to answer questions 1) and 2) above. It works as follows: When a part fails, the broken part is immediately sent to a repair shop. At this point in time, the supply chain manager can choose to request an expedited repair lead time for this part. The repair lead time will be shorter when an expedited repair lead time is requested, but this can only be done for a limited number of repairs per time unit. Using a Markov decision process model, we can show that the optimal expediting rule exhibits the following structure: When the number of parts whose remaining repair lead time is longer than the expedited repair lead time exceeds a certain threshold, the repair of the next broken part will be expedited. The size of this threshold depends on the total number of spare parts in the system, and the forecast of demand in the near future.

Figure 1: Schematic representation of the spare parts supply chain.

Multiple items, fleets, and repair resources

Decisions on how many parts to stock and when to expedite the repair of a part need to be taken for many spare parts that belong to different (train) fleets, but that may use one of several shared repair resources. We devised an algorithm based on decomposition through column generation. To answer question (3) above, we conducted a numerical study that shows that spare part investments can be reduced by 25% on average compared to the state of the art.

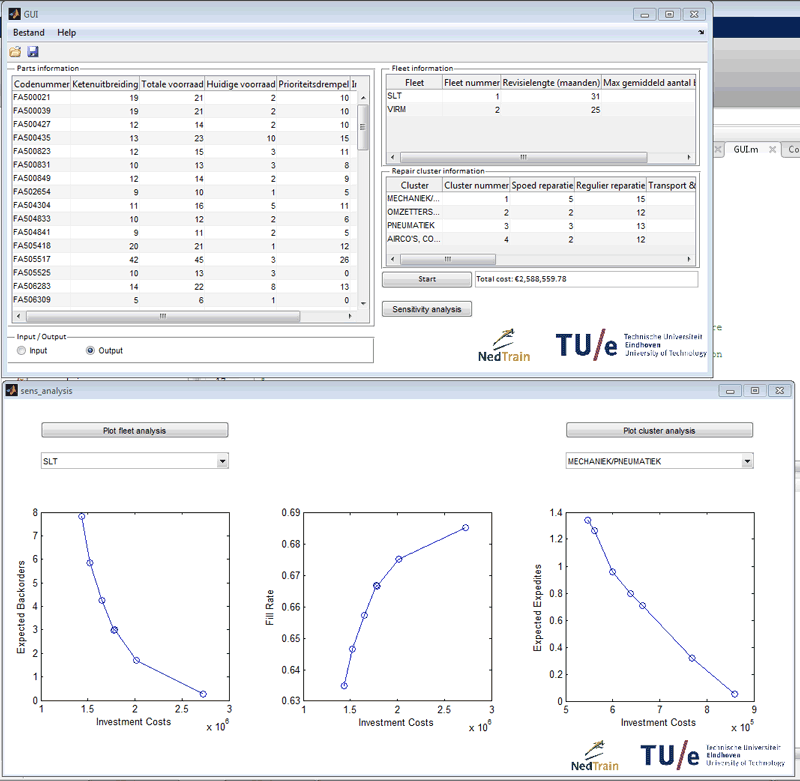

Practical decision support tool

Users that do actual spare parts planning and control can interact with our models through an application we developed. This application is called TRAINcontrol and a screenshot is shown in Figure 2. This app helps users to run sensitivity analyses and answer “what if?”-type questions.

Figure 2: Screenshot of the TRAINcontrol application.

Link:

TRAINcontrol MATLAB app: http://www.mathworks.com/matlabcentral/fileexchange/54498-traincontrol

References:

[1] J.B. Jasper: “Quick Response Solutions: Fedex Critical Inventory Logistics Revitalized”, Fedex White Paper, 2006, http://www.fedex.com/us/supplychain/casestudies/quick_response.pdf.

[2] J. J. Arts: “Spare Parts Planning and Control for Maintenance Operations”, PhD Thesis, Eindhoven University of Technology, http://alexandria.tue.nl/extra2/760116.pdf.

Please contact:

Joachim Arts

TU Eindhoven, The Netherlands