The German VAVID project develops improved techniques for data compression as well as new methods of data analysis, data management and interactive data visualization.

VAVID allows technology firms to get a better grip on the massive amount of data they need to handle. The partners in this project are developing methods to tackle the enormous volumes of data that accumulate at engineering departments. Examples of such data include simulation results and the sensor data received from machines and installations. VAVID works by using comparative analysis and data compression to reduce data to its relevant core. This saves on the costs of data storage and creates the transparency needed by engineers to optimize both production and products. VAVID is being coordinated by the Fraunhofer Institute for Algorithms and Scientific Computing (SCAI) and is receiving 2.2 million € in support from the German Ministry of Education and Research (BMBF) under its Big Data program.

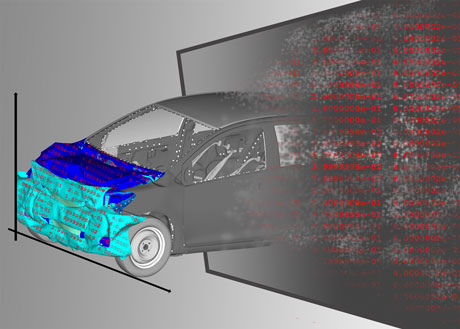

The VAVID project is developing methods to tackle the enormous volumes of data that accumulate at engineering departments, such as data from simulation results.

In today's production environment, numerical simulation has become an indispensable part of product development. Before fabrication begins, it is essential to computationally analyze the product's characteristics in a way that mirrors reality as faithfully as possible. The computations and high-performance computer (HPC) systems required for this task are generating an ever growing mountain of data. An exponential rise in data volumes is also being seen due to the acquisition of sensor data during the operation of machines and plant. These measurement data allow engineers to draw important conclusions on how well control systems are working and how they can further optimize production.

The huge amount of data poses great challenges to technology companies. Moving large data packets around the company or to external partners, and archiving all this data, requires a powerful IT infrastructure, something that is often extremely cost-intensive. Moreover, important information carried by data is frequently not recognized because the company does not have the necessary data extraction methods at its disposal. This is precisely where the VAVID project has set its sights. VAVID is the German acronym for "Vergleichende Analyse von ingenieurrelevanten Mess- und Simulationsdaten" or “Comparative Analysis of Engineering Measurements and Simulation Data.”

The data being studied by the project are numerical simulation results data from the automotive and wind industries as well as measurement data taken from wind turbine monitoring systems. By performing joint and comparative analysis of data from different industries, the partners are in the first project phase developing a methodology for efficient data analysis. These methods and techniques are going into the creation of a high-performance data management system that will allow centralized data storage as well as efficient data access and retrieval.

The second phase will focus on the end user by developing innovative, universally applicable software components that can later be deployed in other industries. Examples of note here include the fields of aviation and mechanical and plant engineering (industrial plant).

The eight partners participating in the project reflect the cooperative effort being made to transfer academic knowledge to industrial practice and to orient research to the needs of industry: Fraunhofer SCAI , Bosch Rexroth Monitoring Systems GmbH in Dresden, GE Global Research in Garching, GNS mbH in Braunschweig, SCALE GmbH in Dresden, SIDACT GmbH in Sankt Augustin, Center for Information Services and High Performance Computing (ZIH) at TU Dresden and the Faculty of Computer Science, Databases department at TU Dresden. The project furthermore cooperates with associated partners AUDI AG in Ingolstadt, ParStream GmbH in Cologne and Volkswagen AG in Wolfsburg. The associated partners from the automotive industry contribute to the joint project by describing the real-world requirements of industry and by supplying relevant sample data for use in the project.

One aim of the VAVID project is to concentrate research and development efforts and point them toward Big Data technologies that can be used in many sectors of industry. A further objective is to generally strengthen the German information and communications technology industry and to boost the competitiveness of German companies. The VAVID project started in September 2014 and is set to run through August 2017.

Link:

http://www.vavid.de

Please contact:

Jochen Garcke, Fraunhofer SCAI

E-mail: